Metal Surface Prep & Anodizing

Controlled anodic oxidation for enhanced material performance.

At Bomar, we provide expertly executed metal preparation and anodizing to ensure your aluminum components meet strict performance and aesthetic standards. From part longevity to finish adhesion, our surface enhancement process supports demanding marine and industrial environments.

What We Offer

Integrated finishing processes that strengthen and protect your parts.

Bomar’s in-house surface treatment services deliver consistent, high-quality finishes that are engineered for performance and longevity.

Aluminum Pre-Treatment

Chemically prepares the surface for enhanced coating or anodizing performance.

Type II Anodizing

Decorative and corrosion-resistant anodizing in clear or dyed finishes.

Type III Anodizing (Hardcoat)

Thick, wear-resistant anodizing for industrial and marine abuse resistance.

Racking & Fixturing Capabilities

Custom jigs to ensure uniform coatings and protect tight tolerance areas.

Post-Anodizing Sealing

Partner with us to scale up production of brackets, covers, plates, and structural assemblies to your spec.

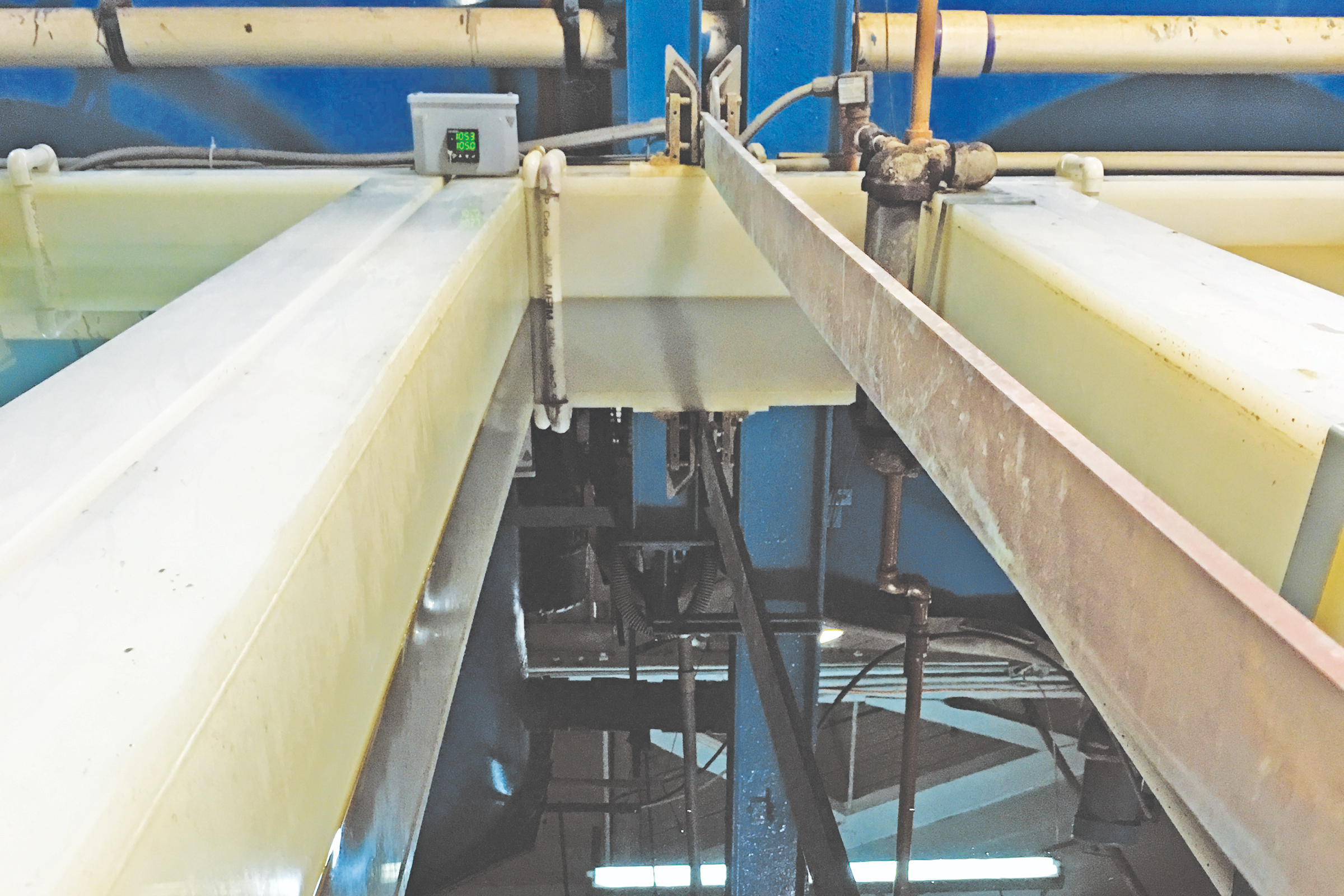

Equipment & Capacity

Dedicated in-house infrastructure enables consistent, repeatable anodizing and pre-treatment processes—ensuring uniform surface quality, color stability, and adherence to tight engineering tolerances across high-volume runs.

Anodizing

Line

Custom-built tanks accommodate both small and mid-size aluminum parts.

Pre-Treat Stations

Controlled cleaning and etching tanks ensure surface readiness.

Racking Systems

Tailored setups for complex geometries and OEM production runs.

Water Quality Control

Filtration systems that maintain bath purity and consistent outcomes.

In-Line Inspections

Color, adhesion, and thickness validated at each stage.

Industries We Serve

Discover the industries that rely on Bomar’s aluminum casting expertise to deliver strong, corrosion-resistant components for demanding environments.

what makes us different

Why Choose Bomar?

Proven Experience

We've built tough parts for boats and ships for decades.

Built to Specs

We shape every part around your needs—no shortcuts.

Everything In-House

From start to finish, we do it all under one roof.

Made in the USA

Engineered and cast in Charlestown, New Hampshire.

More Than Marine – Built for Innovation

At Bomar, our manufacturing capabilities extend beyond the marine industry. From precision CNC fabrication to expert teak craftsmanship and turnkey design-build services, we bring high-quality, American-made solutions to every project.

Metal Fabrication & Bending Service

Aluminum Foundry

CNC Machining

CNC Routing & Laser Cutting

Protective Coatings & Finishes

Start Your Project with Confidence

Whether you need a production partner or support for a new prototype, Bomar’s CNC team is ready to deliver precision-machined results — on time, on spec, and built to last.