Precision-Driven Manufacturing

Manufacturing Capabilities

Explore the full range of manufacturing services that define Bomar’s legacy of quality, performance, and adaptability. From one-off custom solutions to scalable OEM production, our vertically integrated facility supports advanced fabrication, finishing, and assembly under one roof.

Trust in Our 75 Years of American Manufacturing Excellence

CNC Machining

Bomar’s CNC machining services deliver repeatable accuracy across tight-tolerance parts, custom fittings, and production runs.

Multi-Axis CNC Milling

For complex, contoured shapes in aluminum and stainless steel

CNC Turning

Ideal for shafting, bushings, and round-profile parts

Prototyping & Production

Short runs or scalable production for OEM or custom builds

High-Tolerance Accuracy

Tight tolerances maintained for marine, aerospace, and industrial standards

Equipment & Capacity

Multi-axis CNC mills

Precision CNC lathes

Tooling for high-speed steel and carbide cutting

CNC Routing & Laser Cutting

From acrylic panels to aluminum sheet, our routing and cutting systems create detailed profiles at production scale.

Large-format CNC Routing

For complex, contoured shapes in aluminum and stainless steel

Laser Cutting

Ideal for shafting, bushings, and round-profile parts

Complex Profiles

Short runs or scalable production for OEM or custom builds

OEM-Ready Panels

Tight tolerances maintained for marine, aerospace, and industrial standards

Equipment & Capacity

CNC routers with multi-material support

Sheet-fed laser cutting table

CAD/CAM software integration

Aluminum Foundry

From hatch hardware to marine-grade components, our aluminum casting capabilities support intricate and repeatable designs.

Custom Aluminum Castings

For complex, contoured shapes in aluminum and stainless steel

Short-Run & Volume Production

Ideal for shafting, bushings, and round-profile parts

Post-Casting Machining

Short runs or scalable production for OEM or custom builds

Marine-Grade Alloys

Tight tolerances maintained for marine, aerospace, and industrial standards

Equipment & Capacity

Sand casting capabilities

Permanent mold casting stations

On-site post-processing and machining

Protective Coatings & Finishes

We offer durable powder coating and wet paint solutions for long-term corrosion protection and brand-specific aesthetics.

Powder Coating

UV- and salt-resistant finishes for heavy-use environments

Wet Paint Finishes

Smooth, marine-grade color matched options

Custom Color Matching

OEM branding and color consistency

Protective Priming Systems

Enhance coating adheision and service life

Equipment & Capacity

Enclosed spray booths

High-capacity curing ovens

Automated powder coating lines

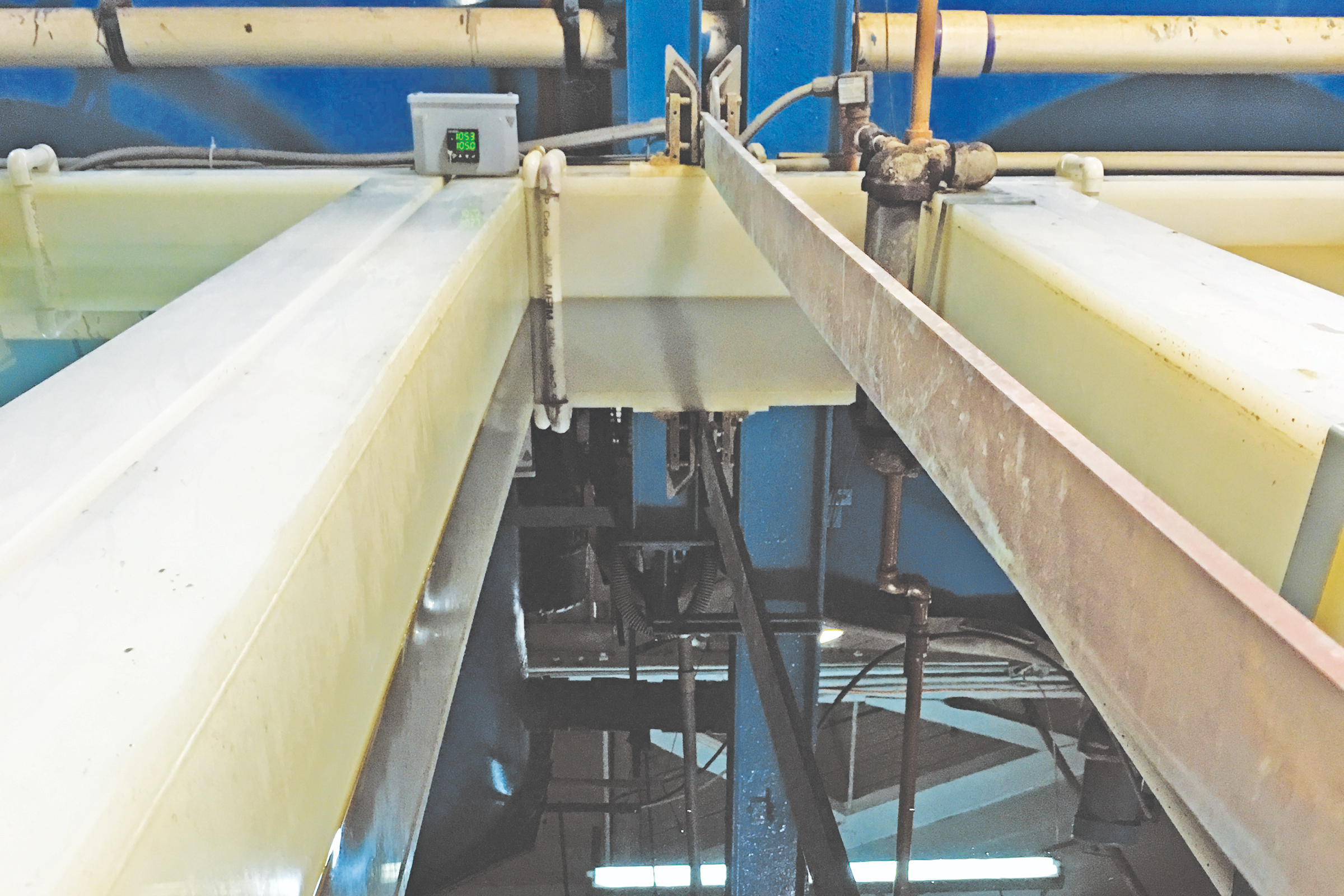

Pre-Treatments & Anodizing

Proper pre-treatment and anodizing improve corrosion resistance and coating durability across marine and industrial components.

Chemical Pre-Treatment

Clean, etch, and prime for better coating adhesion

Clear and Color Anodizing

Durable oxide layers in natural or tinted finishes

Improved Corrosion Resistance

Ideal for aluminum parts exposed to moisture and salt

Hard Anodizing Options

Enhanced wear resistance for moving or high-friction parts

Equipment & Capacity

Anodizing tanks and rinse systems

Chemical etch and sealing stations

Color anodizing capabilities

Metal Fabrication & Bending

From enclosures to custom structures, our fabrication department delivers durable assemblies ready for harsh environments.

Custom Sheet Metal Fabrication

Welded assemblies, brackets, and frames

Tube and Pipe Bending

Structural tubing buent to spec

Precision Brake Forming

Repeatable angles in aluminum and stainless steel

OEM-Ready Solutions

Production-scale capabilities with short lead times

Equipment & Capacity

Brake presses

Tube and pipe benders

MIG, TIG, and spot welding stations

Precision Manufacturing. Industry-Ready Solutions.

From marine-grade closures to custom components for transportation, defense, and industrial applications—Bomar delivers engineered performance with consistent quality. Our in-house capabilities, from CNC machining to finishing, allow us to support complex specs, tight timelines, and high-volume production with confidence.

Partner with Bomar for reliable manufacturing solutions built for your industry.

what makes us different

Why Builders Choose Bomar?

End-to-End Manufacturing

From raw material to finished product, we handle every stage in-house for superior consistency, precision, and accountability.

Customization Without Compromise

Whether it’s a high-volume run or a one-off build, we tailor fabrication and finishing to meet exact design, strength, and finish requirements.

Engineered for Performance

Our components are designed to meet strict tolerances and real-world conditions across marine, defense, and commercial sectors.

Made in the USA

All Bomar products are proudly manufactured in our New Hampshire facility—ensuring responsive support, quality control, and shorter lead times.

Not Sure Where to Start?

Tell us about your build. Whether you’re designing a fleet of patrol vessels or refitting a custom sportfisher, Bomar has the marine closure solution to fit your needs.